Casting

Casting

Silmar® casting resins are one of the best examples of Interplastic’s perfect match to customer’s processes. We offer specially designed resins that match your production requirements, while delivering superior results.

CIPP

CIPP

Whether you’re a municipal professional, an engineer or a CIPP contractor, Interplastic is dedicated to providing you with innovative solutions, a broad product line and support from expert field specialists. Expect consistent, competitively priced, and reliable resins to repair partially or fully deteriorated storm sewer, sewer, culvert and industrial pipes.

Open Mold/Laminating

Open Mold/Laminating

CoREZYN® brand open mold/laminating resins are offered in a wide range of gel and cure time offerings for all types of open mold and laminating applications.

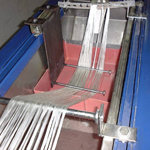

Pultrusion Resins

Pultrusion Resins

Our pultrusion lab and highly capable technical staff are available to develop new formulas or apply an existing formula to give you predictable results. The right resin helps ensure a smooth process and a resulting product that meets your specifications. That’s why we’ve formulated a broad range of resins specifically for the pultrusion market.

RTM/Infusion

RTM/Infusion

Resin Transfer Molding is a closed mold process which utilizes orthophthalic and isophthalic polyester and vinyl ester resins. RTM applications include: automobile panels, sports car bodies, truck body and recreational vehicle components, medical equipment, storage tanks, and marine parts, windmill blades and many more.

SMC/BMC

SMC/BMC

Camper and truck top manufacturing requires excellent surface characteristics and physical properties. Our sheet molding compounds and bulk molding compound resins can be used with a filled or non filled open molding technique to manufacture various truck components. We manufacture the best in fatigue and freeze/thaw-resistant panel resins for recreational vehicle sidewalls and panel resins for tractor-trailer liners and exterior walls as well.