(St. Paul, MN – January 12, 2026) IP Corporation proudly announces the retirement of Rick Graham, National Sales Manager and the promotion of AJ Aldaco to National Technical Sales Manager. Following over 30 years of pioneering gel coat technologies and driving success at HK Research and Interplastic, Rick Graham will retire in January 2026.

David Higgins, Senior Vice President – Gel Coats, shared “We celebrate Rick’s remarkable career and the lasting impact he has had on our business. For more than three decades, his unwavering commitment to our customers and HK Research has fostered exceptional relationships and played a pivotal role in shaping our success. We wish Rick and his family the best in his well-earned retirement”.

Reflecting on his career, Rick Graham said, “It’s amazing to look back at how HK Research and Interplastic have led the way in innovative gel coat technologies. I am deeply grateful to the Higgins family, my colleagues and all our customers for the opportunity to work with so many wonderful friends throughout my career”.

AJ Aldaco will succeed Rick Graham in leading the Technical Sales Representative team, delivering technical support expertise for resin, gel coat, colorants and bonding putty technologies to valued customers and distributor partners.

David Higgins added, “AJ’s two decades of hands-on experience and innovative approach in the composites industry have been instrumental in advancing improvements with our customer’s manufacturing processes. His deep technical expertise, along with his commitment to customer success, make him the ideal leader for our technical sales team. We look forward to reinforcing our “One Team” advantage with integrated technical resources for our customers and distributor partners in the field along with commercial sales representatives”.

According to AJ Aldaco, “Interplastic and HK Research have combined forces to provide value-added technical services focused on helping end-use customers achieve more effective processes utilizing our resin, gel coat, colorants and bonding putty technologies. Our technical sales representatives are active in the field, focusing on customer process optimization. Our customers and distribution partners have direct access to technical support and training, ensuring technicians are equipped to thrive as the industry welcomes new composite professionals. I am especially thankful for Rich Graham’s mentorship and the example he set through the decades.”

Company officials added that the promotion of Aldaco further demonstrates IP Corporation’s commitment to create market leading technologies and service to valued customers, while fostering collaboration and innovation within our organization.

Interplastic has excellent experience and success with CIPP resins. These filled and unfilled isophthalic and vinyl esters are each presented with brief, technical information and a feature/benefit statement

Interplastic has excellent experience and success with CIPP resins. These filled and unfilled isophthalic and vinyl esters are each presented with brief, technical information and a feature/benefit statement A an easy-to read 36 x 24-inch poster that describes common gel coat problems and their solutions.

A an easy-to read 36 x 24-inch poster that describes common gel coat problems and their solutions. Interplastic has been supplying vacuum infusion resins since the 1980’s.

Interplastic has been supplying vacuum infusion resins since the 1980’s.

Our most popular product line. This family of bonding compounds has a proven track record for general purpose adhesion – specifically in the marine industry as a high performance, reliable, weight-reducing, and easy to work with compound.

Our most popular product line. This family of bonding compounds has a proven track record for general purpose adhesion – specifically in the marine industry as a high performance, reliable, weight-reducing, and easy to work with compound.

Silmar® casting resins are one of the best examples of Interplastic’s perfect match to customer’s processes. We offer specially designed resins that match your production requirements, while delivering superior results.

Silmar® casting resins are one of the best examples of Interplastic’s perfect match to customer’s processes. We offer specially designed resins that match your production requirements, while delivering superior results. Whether you’re a municipal professional, an engineer or a CIPP contractor, Interplastic is dedicated to providing you with innovative solutions, a broad product line and support from expert field specialists. Expect consistent, competitively priced, and reliable resins to repair partially or fully deteriorated storm sewer, sewer, culvert and industrial pipes. With more than 40 years of experience with the polyesters and vinyl esters used in cured-in-place pipe applications, you will see how we are dedicated to providing all our customers with smooth installations and years of worry-free performance.

Whether you’re a municipal professional, an engineer or a CIPP contractor, Interplastic is dedicated to providing you with innovative solutions, a broad product line and support from expert field specialists. Expect consistent, competitively priced, and reliable resins to repair partially or fully deteriorated storm sewer, sewer, culvert and industrial pipes. With more than 40 years of experience with the polyesters and vinyl esters used in cured-in-place pipe applications, you will see how we are dedicated to providing all our customers with smooth installations and years of worry-free performance.

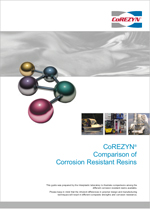

Our corrosion team has developed a series of tough resins for demanding applications. Be it a a stack liner, chemical processing equipment or an entire waste water treatment plant, Interplastic has the right resin for you.

Our corrosion team has developed a series of tough resins for demanding applications. Be it a a stack liner, chemical processing equipment or an entire waste water treatment plant, Interplastic has the right resin for you. CoREZYN brand corrosion and fire retardant resins offer a broad range of product types to meet every need.

CoREZYN brand corrosion and fire retardant resins offer a broad range of product types to meet every need. Marble

Marble CoREZYN brand marine resins are offered in a wide range of gel and cure time offerings to meet every need.

CoREZYN brand marine resins are offered in a wide range of gel and cure time offerings to meet every need. CoREZYN brand open mold/laminating resins are offered in a wide range of gel and cure time offerings for all types of open mold and laminating applications.

CoREZYN brand open mold/laminating resins are offered in a wide range of gel and cure time offerings for all types of open mold and laminating applications. Polymer concrete is part of group of concretes that use polymers to supplement or replace cement as a binder. Parking lots, bridges, ramps, loading docks, driveways, post anchors and sub-floors would be some common applications.

Polymer concrete is part of group of concretes that use polymers to supplement or replace cement as a binder. Parking lots, bridges, ramps, loading docks, driveways, post anchors and sub-floors would be some common applications. Our pultrusion lab and highly capable technical staff are available to develop new formulas or apply an existing formula to give you predictable results. The right resin helps ensure a smooth process and a resulting product that meets your specifications. That’s why we’ve formulated a broad range of resins specifically for the pultrusion market.

Our pultrusion lab and highly capable technical staff are available to develop new formulas or apply an existing formula to give you predictable results. The right resin helps ensure a smooth process and a resulting product that meets your specifications. That’s why we’ve formulated a broad range of resins specifically for the pultrusion market. Pool and Spa are typically a combination of different products. We first recommend a vinyl ester resin coat and follow that with our DCPD laminating resin COR61-AA-131. To figure out the best products for your needs visit our vinyl ester pool/spa page

Pool and Spa are typically a combination of different products. We first recommend a vinyl ester resin coat and follow that with our DCPD laminating resin COR61-AA-131. To figure out the best products for your needs visit our vinyl ester pool/spa page  Our pool & spa resins provide excellent adhesion to acrylic resins, ease of use and superb water resistance. They are available in multiple gel times.

Our pool & spa resins provide excellent adhesion to acrylic resins, ease of use and superb water resistance. They are available in multiple gel times. Resin Transfer Molding is a closed mold process which utilizes orthophthalic and isophthalic polyester and vinyl ester resins. RTM applications include: automobile panels, sports car bodies, truck body and recreational vehicle components, medical equipment, storage tanks, and marine parts, windmill blades and many more.

Resin Transfer Molding is a closed mold process which utilizes orthophthalic and isophthalic polyester and vinyl ester resins. RTM applications include: automobile panels, sports car bodies, truck body and recreational vehicle components, medical equipment, storage tanks, and marine parts, windmill blades and many more. CoREZYN brand sanitary ware/bath resins are designed for filled applications in a variety of gel and cure times to meet every need.

CoREZYN brand sanitary ware/bath resins are designed for filled applications in a variety of gel and cure times to meet every need. Camper and truck top manufacturing requires excellent surface characteristics and physical properties. Our sheet molding compounds and bulk molding compound resins can be used with a filled or non filled open molding technique to manufacture various truck components. We manufacture the best in fatigue and freeze/thaw-resistant panel resins for recreational vehicle sidewalls and panel resins for tractor-trailer liners and exterior walls as well.

Camper and truck top manufacturing requires excellent surface characteristics and physical properties. Our sheet molding compounds and bulk molding compound resins can be used with a filled or non filled open molding technique to manufacture various truck components. We manufacture the best in fatigue and freeze/thaw-resistant panel resins for recreational vehicle sidewalls and panel resins for tractor-trailer liners and exterior walls as well. Silmar brand resins have been the product of choice to the solid surface industry for over 40 years. Our casting labs developed cutting edge polymer technology in collaboration with industry leaders, fine tune our products to meet the exacting demands of surfacing products. Interplastics’ products are typified by consistent color and innovative promoter technology, that handle a multitude of fillers and additives while still delivering the performance features you need.

Silmar brand resins have been the product of choice to the solid surface industry for over 40 years. Our casting labs developed cutting edge polymer technology in collaboration with industry leaders, fine tune our products to meet the exacting demands of surfacing products. Interplastics’ products are typified by consistent color and innovative promoter technology, that handle a multitude of fillers and additives while still delivering the performance features you need. Silmar brand and CoREZYN brand specialty products are offered in many different variations for a variety of market and product applications including; Acylic Bonding, Bowling Ball, Deburring Chips, Filament Winding, Flexible, Grating, Rotational Molding, Tooling and Low Profile, Low Shrink Additives.

Silmar brand and CoREZYN brand specialty products are offered in many different variations for a variety of market and product applications including; Acylic Bonding, Bowling Ball, Deburring Chips, Filament Winding, Flexible, Grating, Rotational Molding, Tooling and Low Profile, Low Shrink Additives. Our series of infusion and pultrusion resins are ideal for infusing even 40 foot or longer bridge pilings or pultruding FRP rebar. These resins are customized for each application.

Our series of infusion and pultrusion resins are ideal for infusing even 40 foot or longer bridge pilings or pultruding FRP rebar. These resins are customized for each application.

Our specialty products have been widely accepted for their performance, durability, and application properties. Specialty gel coats are used in the marine, transportation, and sanitary markets.

Our specialty products have been widely accepted for their performance, durability, and application properties. Specialty gel coats are used in the marine, transportation, and sanitary markets. Our economical, general purpose, MACT compliant gel coats can be found on many different types of composite parts in the sanitary ware market ranging from fiberglass bathtubs, shower units, and wall surrounds to the interior walls of utility vehicles. These gel coats are also used in external applications such as recreation vehicles, utility boxes, cooling towers, and many others.

Our economical, general purpose, MACT compliant gel coats can be found on many different types of composite parts in the sanitary ware market ranging from fiberglass bathtubs, shower units, and wall surrounds to the interior walls of utility vehicles. These gel coats are also used in external applications such as recreation vehicles, utility boxes, cooling towers, and many others.  The sprayable polyester backup coatings are designed to function as a print. They eliminate heat lines and fiber print defects in fiberglass parts, provides high resistance to impact, cracking and elevated temperatures. These products are not designed to provide additional resistance to water and should not be used below the waterline.

The sprayable polyester backup coatings are designed to function as a print. They eliminate heat lines and fiber print defects in fiberglass parts, provides high resistance to impact, cracking and elevated temperatures. These products are not designed to provide additional resistance to water and should not be used below the waterline. Polyester tooling gel coats are designed specifically for manufacturing fiberglass tools and not intended for exterior application. They offer hard, durable, scratch resistant surface with high gloss.

Polyester tooling gel coats are designed specifically for manufacturing fiberglass tools and not intended for exterior application. They offer hard, durable, scratch resistant surface with high gloss. Our sanding primer gel coats have excellent paint compatibility. We offer conductive primers for electrostatic painting process as well. Sanding primers are ideal for any fiberglass composite application requiring a prepared surface prior to finishing.

Our sanding primer gel coats have excellent paint compatibility. We offer conductive primers for electrostatic painting process as well. Sanding primers are ideal for any fiberglass composite application requiring a prepared surface prior to finishing. Surface coats are post applied to composite (FRP) and are formulated with special additives resulting in excellent surface cure. These products produce low gloss, tough, durable surface finish resistant to water spotting and are used in applications ranging from bilg and deck coatings in the marine industry to the exterior post applied coating on chemical storage tanks. Surface coats are available in various custom colors for interior and exterior applications.

Surface coats are post applied to composite (FRP) and are formulated with special additives resulting in excellent surface cure. These products produce low gloss, tough, durable surface finish resistant to water spotting and are used in applications ranging from bilg and deck coatings in the marine industry to the exterior post applied coating on chemical storage tanks. Surface coats are available in various custom colors for interior and exterior applications. Silmar® brand SIL66 resins are the most widely used resin for surfboard manufacturing and hand laminating in the industry. In fact, they are sold throughout the world. These resins feature low color (almost water clear) and excellent UV-resistance (UV-stabilized). They have remarkable stability for consistent viscosity and excellent wet out and gel times. All contain Silmar’s proprietary promoter package designed for surfboard production and room temperature cure.

Silmar® brand SIL66 resins are the most widely used resin for surfboard manufacturing and hand laminating in the industry. In fact, they are sold throughout the world. These resins feature low color (almost water clear) and excellent UV-resistance (UV-stabilized). They have remarkable stability for consistent viscosity and excellent wet out and gel times. All contain Silmar’s proprietary promoter package designed for surfboard production and room temperature cure. The superior transparency and consistency of our Silmar clear gel coats brings out the best in cultured marble and onyx spas, sinks, and countertops. Our extremely durable and MACT-compliant Silmar clear gel coats are top performers in clarity and color.

The superior transparency and consistency of our Silmar clear gel coats brings out the best in cultured marble and onyx spas, sinks, and countertops. Our extremely durable and MACT-compliant Silmar clear gel coats are top performers in clarity and color. These resins are generally unique to each application. Please contact us to develop a resin to meet your needs.

These resins are generally unique to each application. Please contact us to develop a resin to meet your needs. Our vinyl ester barrier coats have a proven track record for the elimination of osmotic blisters below the waterline in marine applications. The additional benefits of these products are improved cosmetics and crack resistance.

Our vinyl ester barrier coats have a proven track record for the elimination of osmotic blisters below the waterline in marine applications. The additional benefits of these products are improved cosmetics and crack resistance.  Camper and truck top manufacturing requires excellent surface characteristics and physical properties. Our sheet molding compounds and bulk molding compound resins can be used with a filled or non filled open molding technique to manufacture various truck components. We manufacture the best in fatigue and freeze/thaw-resistant panel resins for recreational vehicle sidewalls and panel resins for tractor-trailer liners and exterior walls as well.

Camper and truck top manufacturing requires excellent surface characteristics and physical properties. Our sheet molding compounds and bulk molding compound resins can be used with a filled or non filled open molding technique to manufacture various truck components. We manufacture the best in fatigue and freeze/thaw-resistant panel resins for recreational vehicle sidewalls and panel resins for tractor-trailer liners and exterior walls as well. Our R&D team has developed hand lay up, spray up and infusion resins to meet the demanding needs of the transportation market. Be it a tough infusion resin capable of the demands of public transportation or the need for flame retardant, low smoke applications. Our team has or can develop the right resin for you.

Our R&D team has developed hand lay up, spray up and infusion resins to meet the demanding needs of the transportation market. Be it a tough infusion resin capable of the demands of public transportation or the need for flame retardant, low smoke applications. Our team has or can develop the right resin for you. Camper and truck top manufacturing requires excellent surface characteristics and physical properties. Our sheet molding compounds and bulk molding compound resins can be used with a filled or non filled open molding technique to manufacture various truck components. We manufacture the best in fatigue and freeze/thaw-resistant panel resins for recreational vehicle sidewalls and panel resins for tractor-trailer liners and exterior walls as well.

Camper and truck top manufacturing requires excellent surface characteristics and physical properties. Our sheet molding compounds and bulk molding compound resins can be used with a filled or non filled open molding technique to manufacture various truck components. We manufacture the best in fatigue and freeze/thaw-resistant panel resins for recreational vehicle sidewalls and panel resins for tractor-trailer liners and exterior walls as well.

Interplastic bonding compounds are formulated to be hand or machine mixed and applied. This COR-Grip bonding guide with walk you through best practices and set-ups.

Interplastic bonding compounds are formulated to be hand or machine mixed and applied. This COR-Grip bonding guide with walk you through best practices and set-ups. Lists CoREZYN resin product offerings compared to other manufacturers. Describes the performance characteristics of the CoREZYN products.

Lists CoREZYN resin product offerings compared to other manufacturers. Describes the performance characteristics of the CoREZYN products.