(St. Paul, MN – February 16th, 2024) Interplastic Corporation announced today that it will raise the price of both Silmar and CoREZYN brand polyester resins, gel coats, bonding compounds, colorants and vinyl ester resins up to $0.07 per pound. This increase will take effect for all shipments on or after March 16th, 2024.

Continue reading

(St. Paul, MN – October 23, 2023) Interplastic announced that it will be showcasing its CoREZYN® and Simlar® brand of products at the 2023 CAMX show. The event will be taking place at the Georgia World Congress Center October 30 – November 2, 2023, in Atlanta, GA.

(St. Paul, MN – July 12, 2023) Erik Levy, IP Corporation’s Chief Operating Officer, today announced the 2023 recipients of the Scholars Award sponsored by Interplastic Corporation in affiliation with the American Composites Manufacturers Association (ACMA) and the International Cast Polymer Association (ICPA).

The six well-deserving high school graduates and their company affiliations are: Micaela Barbery, Rochester Hills, MI (Teijin Automotive Technologies); Abigail Grace Linderman, Birmingham, AL (Huber Engineered Materials) Kaila Arthur, Richmond, IN (Creative Composite Group); Brady Brownell, Salem, OR (Miles Fiberglass); Alayna Crawford, Newark, OH (Owen’s Corning); and Danielle McIIwain, South Bend, IN (Superior Oil). This year we provided each winner an award of $3,500 to be used towards their studies at a four-year college or university of their choice.

Oct. 23-25, 2023 | Edmonton, Alberta | Booth # 219

(St. Paul, MN – January 4th, 2023) Chris Deel, Interplastic National Sales Manager, announced that Matt Butler has joined the Interplastic Corporation team as a Regional Sales Manager. Matt will be responsible for managing sales covering the north central states.

Matt comes to Interplastic with over 18 years of experience in sales, marketing, business development, and supply chain. He also earned his Bachelor’s in Business Administration from The University of Toledo.

(St. Paul, MN – September 22nd, 2022) Erik Levy, IP Corporation’s Chief Operating Officer, today announced the 2022 recipients of the Scholars Award sponsored by Interplastic Corporation in affiliation with the American Composites Manufacturers Association (ACMA) and the International Cast Polymer Association (ICPA).

The six well-deserving high school graduates and their company affiliations are: Celina Liang, Morgantown, WV (West Virginia University); Kailyn Spitler, Greenwood, IN (Superior Industrial Solutions) Stella Marti, San Antonio, TX (Inpro Corp); Peyton Woodlief, Cypress, TX (Enduro Composites); Katie Madlem, Wakarusa, IN (Frost Engineering & Consulting); and Nicole Elchert, Riegel, OH (Johns Manville). This year we provided each winner an award of $3,500 to be used towards their studies at a four-year college or university of their choice.

PRESS RELEASE

(St. Paul, MN – November 9th, 2020) Interplastic Corporation, a division of IP Corporation, is excited to announce the launch of their new website which incorporates a great modern new look and functionality. You can check it out at www.interplastic.com.

For superior quality and color matching, choose CoREZYN.

For superior quality and color matching, choose CoREZYN.

Interplastic has excellent experience and success with CIPP resins. These filled and unfilled isophthalic and vinyl esters are each presented with brief, technical information and a feature/benefit statement

Interplastic has excellent experience and success with CIPP resins. These filled and unfilled isophthalic and vinyl esters are each presented with brief, technical information and a feature/benefit statement

A an easy-to read 36 x 24-inch poster that describes common gel coat problems and their solutions.

A an easy-to read 36 x 24-inch poster that describes common gel coat problems and their solutions.

Interplastic has been supplying vacuum infusion resins since the 1980’s.

Interplastic has been supplying vacuum infusion resins since the 1980’s.

Our architectural/Theme Park resins provide the best balance between flame retardancy, smoke generation and processibility to meet the needs of all applications.

Our most popular product line. This family of bonding compounds has a proven track record for general purpose adhesion – specifically in the marine industry as a high performance, reliable, weight-reducing, and easy to work with compound.

Our most popular product line. This family of bonding compounds has a proven track record for general purpose adhesion – specifically in the marine industry as a high performance, reliable, weight-reducing, and easy to work with compound.

Recommended for any FRP to FRP bonding application or as a filler material. This includes general structural bonding, hull and deck assemblies, building contours in the corners of the laminate, smoothing edges of core materials, strake filling, crack filling, and transom builds.

These products should be used where improved corrosion resistance or hydrolytic stability is desired or required.

PA-176-PMMF

- Isophthalic adhesive designed for resistance to fuels

- Reinforced for added strength when filling cracks, corners, and angles

PA-181-VHMN (vinyl ester)

- Vinyl ester resin base for corrosion resistance and hydrolytic stability

These products are ideal for industrial or construction markets that require fire resistance.

PR-235-VHLN

- Modified vinyl ester radius compound

- Designed for use in composite fabrication industry using Interplastic low flame spread and low smoke development resin

- Initiated with benzoyl peroxide (BPO)

Silmar® casting resins are one of the best examples of Interplastic’s perfect match to customer’s processes. We offer specially designed resins that match your production requirements, while delivering superior results.

Silmar® casting resins are one of the best examples of Interplastic’s perfect match to customer’s processes. We offer specially designed resins that match your production requirements, while delivering superior results.

Whether you’re a municipal professional, an engineer or a CIPP contractor, Interplastic is dedicated to providing you with innovative solutions, a broad product line and support from expert field specialists. Expect consistent, competitively priced, and reliable resins to repair partially or fully deteriorated storm sewer, sewer, culvert and industrial pipes. With more than 40 years of experience with the polyesters and vinyl esters used in cured-in-place pipe applications, you will see how we are dedicated to providing all our customers with smooth installations and years of worry-free performance.

Whether you’re a municipal professional, an engineer or a CIPP contractor, Interplastic is dedicated to providing you with innovative solutions, a broad product line and support from expert field specialists. Expect consistent, competitively priced, and reliable resins to repair partially or fully deteriorated storm sewer, sewer, culvert and industrial pipes. With more than 40 years of experience with the polyesters and vinyl esters used in cured-in-place pipe applications, you will see how we are dedicated to providing all our customers with smooth installations and years of worry-free performance.

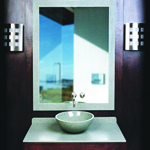

Sanitary Ware/Bath

Pool/Spa

Our corrosion team has developed a series of tough resins for demanding applications. Be it a a stack liner, chemical processing equipment or an entire waste water treatment plant, Interplastic has the right resin for you.

Our corrosion team has developed a series of tough resins for demanding applications. Be it a a stack liner, chemical processing equipment or an entire waste water treatment plant, Interplastic has the right resin for you.

CoREZYN brand corrosion and fire retardant resins offer a broad range of product types to meet every need.

CoREZYN brand corrosion and fire retardant resins offer a broad range of product types to meet every need.

Our line of marine resins provide excellent surface finish, water resistance and ease of use no matter which process you use. Our off the shelf products provide fast fill, flexible gel times and great cosmetics for infusion or hand layup. We can customize the right product for your application.

Marble

Marble

Silmar pioneered marble casting resins and they deliver the strength, durability and beauty needed in cultured marble and onyx products. With hundreds of millions of pounds of sold worldwide, SIL90BA-585 became the standard by which competitive marble resins are judged. Resins used in cultured marble applications need color consistency, excellent air release properties, and good thermal shock properties to withstand years of use.

CoREZYN brand marine resins are offered in a wide range of gel and cure time offerings to meet every need.

CoREZYN brand marine resins are offered in a wide range of gel and cure time offerings to meet every need.

CoREZYN brand open mold/laminating resins are offered in a wide range of gel and cure time offerings for all types of open mold and laminating applications.

CoREZYN brand open mold/laminating resins are offered in a wide range of gel and cure time offerings for all types of open mold and laminating applications.

Polymer concrete is part of group of concretes that use polymers to supplement or replace cement as a binder. Parking lots, bridges, ramps, loading docks, driveways, post anchors and sub-floors would be some common applications.

Polymer concrete is part of group of concretes that use polymers to supplement or replace cement as a binder. Parking lots, bridges, ramps, loading docks, driveways, post anchors and sub-floors would be some common applications.

Our pultrusion lab and highly capable technical staff are available to develop new formulas or apply an existing formula to give you predictable results. The right resin helps ensure a smooth process and a resulting product that meets your specifications. That’s why we’ve formulated a broad range of resins specifically for the pultrusion market.

Our pultrusion lab and highly capable technical staff are available to develop new formulas or apply an existing formula to give you predictable results. The right resin helps ensure a smooth process and a resulting product that meets your specifications. That’s why we’ve formulated a broad range of resins specifically for the pultrusion market.

Pool and Spa are typically a combination of different products. We first recommend a vinyl ester resin coat and follow that with our DCPD laminating resin COR61-AA-131. To figure out the best products for your needs visit our vinyl ester pool/spa page here.

Pool and Spa are typically a combination of different products. We first recommend a vinyl ester resin coat and follow that with our DCPD laminating resin COR61-AA-131. To figure out the best products for your needs visit our vinyl ester pool/spa page here.

Our pool & spa resins provide excellent adhesion to acrylic resins, ease of use and superb water resistance. They are available in multiple gel times.

Our pool & spa resins provide excellent adhesion to acrylic resins, ease of use and superb water resistance. They are available in multiple gel times.

Resin Transfer Molding is a closed mold process which utilizes orthophthalic and isophthalic polyester and vinyl ester resins. RTM applications include: automobile panels, sports car bodies, truck body and recreational vehicle components, medical equipment, storage tanks, and marine parts, windmill blades and many more.

Resin Transfer Molding is a closed mold process which utilizes orthophthalic and isophthalic polyester and vinyl ester resins. RTM applications include: automobile panels, sports car bodies, truck body and recreational vehicle components, medical equipment, storage tanks, and marine parts, windmill blades and many more.

CoREZYN brand sanitary ware/bath resins are designed for filled applications in a variety of gel and cure times to meet every need.

CoREZYN brand sanitary ware/bath resins are designed for filled applications in a variety of gel and cure times to meet every need.

Camper and truck top manufacturing requires excellent surface characteristics and physical properties. Our sheet molding compounds and bulk molding compound resins can be used with a filled or non filled open molding technique to manufacture various truck components. We manufacture the best in fatigue and freeze/thaw-resistant panel resins for recreational vehicle sidewalls and panel resins for tractor-trailer liners and exterior walls as well.

Camper and truck top manufacturing requires excellent surface characteristics and physical properties. Our sheet molding compounds and bulk molding compound resins can be used with a filled or non filled open molding technique to manufacture various truck components. We manufacture the best in fatigue and freeze/thaw-resistant panel resins for recreational vehicle sidewalls and panel resins for tractor-trailer liners and exterior walls as well.

Silmar brand resins have been the product of choice to the solid surface industry for over 40 years. Our casting labs developed cutting edge polymer technology in collaboration with industry leaders, fine tune our products to meet the exacting demands of surfacing products. Interplastics’ products are typified by consistent color and innovative promoter technology, that handle a multitude of fillers and additives while still delivering the performance features you need.

Silmar brand resins have been the product of choice to the solid surface industry for over 40 years. Our casting labs developed cutting edge polymer technology in collaboration with industry leaders, fine tune our products to meet the exacting demands of surfacing products. Interplastics’ products are typified by consistent color and innovative promoter technology, that handle a multitude of fillers and additives while still delivering the performance features you need.

Silmar brand and CoREZYN brand specialty products are offered in many different variations for a variety of market and product applications including; Acylic Bonding, Bowling Ball, Deburring Chips, Filament Winding, Flexible, Grating, Rotational Molding, Tooling and Low Profile, Low Shrink Additives.

Silmar brand and CoREZYN brand specialty products are offered in many different variations for a variety of market and product applications including; Acylic Bonding, Bowling Ball, Deburring Chips, Filament Winding, Flexible, Grating, Rotational Molding, Tooling and Low Profile, Low Shrink Additives.

Our series of infusion and pultrusion resins are ideal for infusing even 40 foot or longer bridge pilings or pultruding FRP rebar. These resins are customized for each application.

Our series of infusion and pultrusion resins are ideal for infusing even 40 foot or longer bridge pilings or pultruding FRP rebar. These resins are customized for each application.

Silmar® casting resins are one of the best examples of Interplastic’s perfect match to customer’s processes. We offer specially designed resins that match your production requirements, while delivering superior results

Continue reading

Interplastic has two lines of colorants – standard and high performance. These products are specially formulated for standard unsaturated polyester systems to be used in laminating resins, casting resins, and molding compounds.

| Standard Line | High Performance Line | ||

| B-168-CZZ | Black | B-1383-CZZ | Black |

| A-627B-CZZ | Blue | A-766B-CZZ | Blue |

| G-3504-CZZ | Green | G-745B-CZZ | Green |

| R-234B-CZZ | Red | R-530B-CZZ | Red |

| A-3643H-CZZ | Violet | A-530B-CZZ | Violet |

| Y-727B-CZZ | Yellow | Y-363B-CZZ | Yellow |

| W-110-CZZ | White | W-1292B-CZZ | White |

The grinding vehicle and pigments are chosen for their stability and compatibility with minimal effect on cure properties of the unsaturated polyester resins. Interplastic can use the single pigment dispersions to customize any color our customers’ request.

Our high performance colorants are higher viscosity and highly stabilized to be used above and below the waterline.

Our standard lines of colorants have lower viscosity and work well in many different applications. Both colorants lines have excellent batch-to-batch consistency to ensure proper color every time the colorant is manufactured.

Some colorants are available in FDA approvable versions.

Our specialty products have been widely accepted for their performance, durability, and application properties. Specialty gel coats are used in the marine, transportation, and sanitary markets.

Our specialty products have been widely accepted for their performance, durability, and application properties. Specialty gel coats are used in the marine, transportation, and sanitary markets.

Our economical, general purpose, MACT compliant gel coats can be found on many different types of composite parts in the sanitary ware market ranging from fiberglass bathtubs, shower units, and wall surrounds to the interior walls of utility vehicles. These gel coats are also used in external applications such as recreation vehicles, utility boxes, cooling towers, and many others. Continue reading

Our economical, general purpose, MACT compliant gel coats can be found on many different types of composite parts in the sanitary ware market ranging from fiberglass bathtubs, shower units, and wall surrounds to the interior walls of utility vehicles. These gel coats are also used in external applications such as recreation vehicles, utility boxes, cooling towers, and many others. Continue reading

The sprayable polyester backup coatings are designed to function as a print. They eliminate heat lines and fiber print defects in fiberglass parts, provides high resistance to impact, cracking and elevated temperatures. These products are not designed to provide additional resistance to water and should not be used below the waterline.

The sprayable polyester backup coatings are designed to function as a print. They eliminate heat lines and fiber print defects in fiberglass parts, provides high resistance to impact, cracking and elevated temperatures. These products are not designed to provide additional resistance to water and should not be used below the waterline.

Polyester tooling gel coats are designed specifically for manufacturing fiberglass tools and not intended for exterior application. They offer hard, durable, scratch resistant surface with high gloss.

Polyester tooling gel coats are designed specifically for manufacturing fiberglass tools and not intended for exterior application. They offer hard, durable, scratch resistant surface with high gloss.

Our sanding primer gel coats have excellent paint compatibility. We offer conductive primers for electrostatic painting process as well. Sanding primers are ideal for any fiberglass composite application requiring a prepared surface prior to finishing.

Our sanding primer gel coats have excellent paint compatibility. We offer conductive primers for electrostatic painting process as well. Sanding primers are ideal for any fiberglass composite application requiring a prepared surface prior to finishing.

Surface coats are post applied to composite (FRP) and are formulated with special additives resulting in excellent surface cure. These products produce low gloss, tough, durable surface finish resistant to water spotting and are used in applications ranging from bilg and deck coatings in the marine industry to the exterior post applied coating on chemical storage tanks. Surface coats are available in various custom colors for interior and exterior applications.

Surface coats are post applied to composite (FRP) and are formulated with special additives resulting in excellent surface cure. These products produce low gloss, tough, durable surface finish resistant to water spotting and are used in applications ranging from bilg and deck coatings in the marine industry to the exterior post applied coating on chemical storage tanks. Surface coats are available in various custom colors for interior and exterior applications.

Silmar® brand SIL66 resins are the most widely used resin for surfboard manufacturing and hand laminating in the industry. In fact, they are sold throughout the world. These resins feature low color (almost water clear) and excellent UV-resistance (UV-stabilized). They have remarkable stability for consistent viscosity and excellent wet out and gel times. All contain Silmar’s proprietary promoter package designed for surfboard production and room temperature cure.

Silmar® brand SIL66 resins are the most widely used resin for surfboard manufacturing and hand laminating in the industry. In fact, they are sold throughout the world. These resins feature low color (almost water clear) and excellent UV-resistance (UV-stabilized). They have remarkable stability for consistent viscosity and excellent wet out and gel times. All contain Silmar’s proprietary promoter package designed for surfboard production and room temperature cure.

Marine gel coats are high performance coatings designed for the most demanding applications. These gel coats are used in a variety of marine applications from high performance speed boats to luxury yachts. Our gel coats are also used successfully in architectural applications as well as fiberglass swimming pools.

Marine gel coats are high performance coatings designed for the most demanding applications. These gel coats are used in a variety of marine applications from high performance speed boats to luxury yachts. Our gel coats are also used successfully in architectural applications as well as fiberglass swimming pools.

The superior transparency and consistency of our Silmar clear gel coats brings out the best in cultured marble and onyx spas, sinks, and countertops. Our extremely durable and MACT-compliant Silmar clear gel coats are top performers in clarity and color.

The superior transparency and consistency of our Silmar clear gel coats brings out the best in cultured marble and onyx spas, sinks, and countertops. Our extremely durable and MACT-compliant Silmar clear gel coats are top performers in clarity and color.

These resins are generally unique to each application. Please contact us to develop a resin to meet your needs.

These resins are generally unique to each application. Please contact us to develop a resin to meet your needs.

Our vinyl ester barrier coats have a proven track record for the elimination of osmotic blisters below the waterline in marine applications. The additional benefits of these products are improved cosmetics and crack resistance. Continue reading

Our vinyl ester barrier coats have a proven track record for the elimination of osmotic blisters below the waterline in marine applications. The additional benefits of these products are improved cosmetics and crack resistance. Continue reading

Camper and truck top manufacturing requires excellent surface characteristics and physical properties. Our sheet molding compounds and bulk molding compound resins can be used with a filled or non filled open molding technique to manufacture various truck components. We manufacture the best in fatigue and freeze/thaw-resistant panel resins for recreational vehicle sidewalls and panel resins for tractor-trailer liners and exterior walls as well.

Camper and truck top manufacturing requires excellent surface characteristics and physical properties. Our sheet molding compounds and bulk molding compound resins can be used with a filled or non filled open molding technique to manufacture various truck components. We manufacture the best in fatigue and freeze/thaw-resistant panel resins for recreational vehicle sidewalls and panel resins for tractor-trailer liners and exterior walls as well.

Our R&D team has developed hand lay up, spray up and infusion resins to meet the demanding needs of the transportation market. Be it a tough infusion resin capable of the demands of public transportation or the need for flame retardant, low smoke applications. Our team has or can develop the right resin for you.

Our R&D team has developed hand lay up, spray up and infusion resins to meet the demanding needs of the transportation market. Be it a tough infusion resin capable of the demands of public transportation or the need for flame retardant, low smoke applications. Our team has or can develop the right resin for you.

These resins comprise our premium offerings in infrastructure building and repair, as well as corrosion resistance. They are very versatile in the wide range of capabilities they offer.

Continue reading

Need excerpt content.

Continue reading

Cultured Marble/Onyx

Marble

Silmar pioneered marble casting resins and they deliver the strength, durability and beauty needed in cultured marble and onyx products. With hundreds of millions of pounds of sold worldwide, SIL90BA-585 became the standard by which competitive marble resins are judged. Resins used in cultured marble applications need color consistency, excellent air release properties, and good thermal shock properties to withstand years of use.

SIL90BA-1321

This is our unsaturated polyester resin; pre-promoted for ambient temperature cure with MEKP catalyst. It contains styrene monomer. This resin has a natural matrix color, good air release, medium viscosity, high filler loading and excellent physical properties. It is designed for general purpose cast marble applications.

SIL90BA-770CH

Our unsaturated polyester resin pre-promoted for room temperature cure with MEK peroxide. It contains styrene monomer. This resin is a light colored, high viscosity polyester resin designed for synthetic marble casting applications. It's unique cure profile, low shrinkage and reduced exothermal development makes this product very forgiving and ideal for bathtub and shower receptor fabrication.

SIL90BA-1247

An unsaturated polyester resin pre-promoted for ambient temperature cure with MEKP catalyst. It contains styrene monomer. It has a natural matrix color, good air release, high viscosity, medium gel time and excellent physical properties. It is designed for general purpose cast marble application.

Dual Purpose

Our SIL94 Series resins are the perfect choice when marble, onyx or granite products are desired to be made using the same resin. For color consistency, versatility and inventory control the SIL94 products offer the manufacturer the best match.

SIL94BA-993B

Onyx

The Silmar SIL92BA-793C onyx resin has been formulated to specifically meet our customer’s needs in order to make the best onyx castings. It features a good, consistent cure while maintaining very low color.

DCPD Marble

SIL91BB-2405A

SIL91BB-2455

Solid Surface/Engineered Stone

Solid Surface/Engineered Stone

SIL93BE-1302A

SIL93BE-1302A is a premium solid surface casting resin. It is 100% iso-NPG, UV-stabilized and acrylic-modified with excellent air release. This resin cures with a bluish cast compared to SIL93BE-1122B.

Our R&D team has developed hand lay up, spray up and infusion resins to meet the demanding needs of the transportation market. Be it a tough infusion resin capable of the demands of public transportation or the need for flame retardant, low smoke applications. Our team has or can develop the right resin for you.

Our R&D team has developed hand lay up, spray up and infusion resins to meet the demanding needs of the transportation market. Be it a tough infusion resin capable of the demands of public transportation or the need for flame retardant, low smoke applications. Our team has or can develop the right resin for you.

Camper and truck top manufacturing requires excellent surface characteristics and physical properties. Our sheet molding compounds and bulk molding compound resins can be used with a filled or non filled open molding technique to manufacture various truck components. We manufacture the best in fatigue and freeze/thaw-resistant panel resins for recreational vehicle sidewalls and panel resins for tractor-trailer liners and exterior walls as well.

Camper and truck top manufacturing requires excellent surface characteristics and physical properties. Our sheet molding compounds and bulk molding compound resins can be used with a filled or non filled open molding technique to manufacture various truck components. We manufacture the best in fatigue and freeze/thaw-resistant panel resins for recreational vehicle sidewalls and panel resins for tractor-trailer liners and exterior walls as well.

Continue reading

COR52-AA-480

COR52-AA-085ECO

A 15-Year Study of the Effective Use of Permeation Barriers in Marine Composites to Prevent Corrosion and Blistering.

Big money stakes and lots of fun. That describes Poker Runs and they have taken boating to yet another level. In offshore racing, speed is all that counts but in Poker Runs, it’s the hand you’re dealt.

An engineering alliance lead to the successful creation of a 123 foot (37.5 m) long hull using the vacuum infusion process (VIP) and certification of the yacht by Det Norske Veritas (DNV).

Interplastic bonding compounds are formulated to be hand or machine mixed and applied. This COR-Grip bonding guide with walk you through best practices and set-ups.

Interplastic bonding compounds are formulated to be hand or machine mixed and applied. This COR-Grip bonding guide with walk you through best practices and set-ups.

Lists CoREZYN resin product offerings compared to other manufacturers. Describes the performance characteristics of the CoREZYN products.

Lists CoREZYN resin product offerings compared to other manufacturers. Describes the performance characteristics of the CoREZYN products.

Superior is a major provider of industrial products and services supplying a broad and diverse industry. We have the highest commitment to technical innovation, unparalleled service, and sound environmental practices.

Over more than 75 years, Superior has evolved into a leading independent chemical supplier and fiberglass distributor. Our growth has come from innovation — continuously searching for new, better ways to meet your needs. Our reputation has been built on our passion — bringing the best solutions to the marketplace and providing the highest level of service to our customers.

Revchem Composites offers an extensive selection of materials, supplies, and equipment to the composites industry. Their extensive inventory, technical expertise, on-site support, personalized customer service and fast, flexible delivery make them a valuable partner to the composites industry. They carry more than 4,000 products from over 200 suppliers. Their five west coast distribution centers supply customers throughout North America, South America, Europe, and Asia. Their technical sales team provides expert advice and on-site support. Revchem Composites has been Delivering Composite Solutions Daily since 1975.

Fibre-Wound’s reputation is based on its many years of proven design and engineering expertise, corrosion problem-solving abilities and installation of non-metallic, polymeric and composite materials, products and equipment in the petrochemical, pulp/paper, chlor-alkali, precious metals refining, minerals and metals beneficiation, power generation, water and effluent treatment and allied type industries. Our abilities include:

- Underground applications incorporating corrosion-resistant cooling piping for sea water intakes, plant surface spillage and contaminated water drainage piping.

- High pressure fire mains, corrosion resistant linings to sumps, chambers and collection pits.

- Surface linings and protective coatings to concrete flooring, bunds, plinths and equipment bases.

- Liquids and gas pressure vessels and storage tanks.

- Custom designed and fabricated plant and equipment.

- Piping, ducting, fans, pumps, valves fittings and in-line piping accessories.

- Gas scrubbing and cleaning systems, liquid filters, mist eliminators and strainers.

A variety of reinforced plastics processes are used by the manufacturers of these products, including gelcoating and laminating, hand lay-up, spray lay-up, filament winding, centrifugal casting and pultrusion. The type of product determines the choice of production method, and a considerable investment has been made in developing the skills to accomplish this. Materials used include unsaturated polyesters, DCPD polyesters, epoxies, vinyl esters, phenolics and hybrids thereof. Reinforcements include glassfibre as well as carbon and polyaramid fibre and combinations of these.

OP Fiberglass and Marine Supplies Ltd. is a full service distributor representing Interplastic Corporation in the Maritime Provinces of Newfoundland.

Contact their offices for more information:

OP Fiberglass and Marine Supplies Ltd.

22 Sagona Avenue, Donovans Industrial Park

Mount Pearl, NF

A1N 4R2 Canada

Toll Free: 877-747-3745

Phone: 709-747-3745

Fax: 709-747-3977

Omya has more than 130 years of experience. The company distributes catalysts, inorganic chemicals, pigments, lubricants, rust/corrosion/stain inhibitors, plasticizers, resins, and thickening agents. Its customers include companies in the adhesives and sealants, paints and coatings, plastics and rubber, and electronics industries. Their knowledgeable staff is ready to assist with all technical needs.

North American Composites is a national distributor of composites raw materials based in Lino Lakes, MN. For over 30 years, NAC has served manufacturers in marine, cast polymer, corrosion, construction, consumer, and related composites industries.

They provide their customers with local service through distribution centers in the U.S. and Canada. Each of their locations serves local customers with fast, efficient deliveries of the products they need while providing a wide range of services in manufacturing equipment, process development and regulatory assistance.

Min-Chem Canada, Inc., is a full service distributor representing Interplastic Corporation in province of Ontario and Quebec.

Contact their offices for more information:

Min-Chem Canada, Inc.

400, rue Joseph Carrier

Vaudreuil, Quebec J7V 5V5

Phone: 450-424-0174

Fax: 450-424-9112

460 Wyecroft Road

Oakville, Ontario L6K 2G7

Phone: 905-842-8300

Fax: 905-842-8906

Fiberglass Hawaii, Inc. was established in 1966. Based in Honolulu, there also are branches in Maui, and Wahiawa in Hawaii and Ventura and Los Angeles in California. Fiberglass Hawaii is a worldwide supplier of resin and accessories to the surfing and windsurfing industries, as well as a full-line distributor of raw materials and equipment to the marine, industrial, cultured marble and fishing rod and lure markets.

A line of repackaged fiberglass and resins is supplied to all hardware and hobby stores in Hawaii and the Pacific Islands. Fiberglass Hawaii prides itself on being recognized as an authority and innovator for fabrics and resins – both polyester and epoxy systems – for the sports of surfing and windsurfing.

Contact their offices for more information:

Honolulu

Ted Wilson, President

Fiberglass Hawaii,Inc.

1377 Colburn Street

Honolulu, HI 96817

PH: 808/847-3951

Fax: 808/841-2108

Sales@FiberglassHawaii.com

www.fiberglasshawaii.com

Fiberglass Florida, Inc. provides fiberglass products, resins, supplies and materials for surfboard manufacturing and repair, boat manufacturing and repair, auto parts manufacturing and repair and composite airplane manufacturing and modifications.

Fiberglass Florida, Inc.

320 Paint Street

Rockledge, FL 32955

(800) 699-4527

(321) 639-3046

(321) 639-3048 FAX

Fiberglass Coatings, Inc. has the largest display of fiberglass materials and is committed to meeting the needs of its customers, from the hobbyist to the professional. They provide products and support to individuals and to major manufacturers of composite fabricated products alike. They offer a wide variety of products and supplies to fit almost any application.

Fiberglass Coatings

4301 A 34th Street N.

St. Petersburg, FL 33713

(800) 272-7890

(727) 327-6691 fax

Composites One LLC is a family-owned distributor with 60 years of composites experience. Their network of 32 local distribution centers is dedicated to serving the composites manufacturing industry. They assist customers with product selection, specification, delivery, handling and use. They support customers with processes, including closed mold technologies, regulatory compliance and value-added services. Composites One has more than 30,000 products from over 400 supplier partners reaching 9,000 customers.

PRESS RELEASE

FOR IMMEDIATE RELEASE

Interplastic Corporation today announced that is has named Univar Solutions as a new distribution partner for its unsaturated polyester and vinyl ester resins, gel coats, colorants and bonding compounds in Eastern Canada.

Univar Solutions is a global partner for value-added distribution of chemistry and related products and services with an extensive network throughout Canada. “The partnership with Univar Solutions will allow us to extend our reach in Manitoba, Ontario, Quebec and points further east. They will provide product inventory with local delivery and service to customers in eastern Canada.” said Steve Wetzel, VP of Sales of Interplastic Corporation. “We look forward to building a strong partnership with them.”

“We are excited to partner with Interplastic Corporation. The combination of Interplastic’s superior resin and gel coat technology, along with Univar’s capabilities and market reach, will allow us to expand our presence in the Canadian Composites market ”, says Poonam McGuire, Product Manager for Composites at Univar Solutions Canada.

Jean Lessard, Director of Core Product Management and Supply at Univar Solutions added, “this new partnership with Interplastic will allow Univar Solutions to offer innovative products to our composites customers”.

About Univar Solutions

Univar Solutions (NYSE: UNVR) is a leading global chemical and ingredient distributor and provider of value added services to customers across a wide range of industries. With the industry’s largest private transportation fleet and North American sales force, a vast supplier network, deep market and regulatory knowledge, world-class formulation and recipe development, unparalleled logistics know-how, and industry-leading digital tools, Univar Solutions is a committed ally to customers and suppliers, helping them anticipate, navigate, and leverage meaningful growth opportunities.

PRESS RELEASE

FOR IMMEDIATE RELEASE

Jason Schiro, Business Manager – Pipeline Remediation Polymers, announced today that Interplastic Corporation has been granted a patent for their new commercially available ONEstep CIPP resin system. This patented system (US Patent 10,131,766) is designed to be a simpler, safer process for initiating a Cured-in-Place Pipe (CIPP) resin.

Interplastic’s ONEstep product offers the benefit of using a single, liquid initiator. The system provides mechanical properties, cure, pot life and corrosion resistance comparable to currently available CIPP resins. ONEstep is available with several different resin formulations, both neat and enhanced. “We believe these systems will help develop and innovate the CIPP market. We are excited about ONEstep, it’s truly a unique offering that can change the path of CIPP lining”, said Jason Schiro. “We have already supplied over one million pounds to the CIPP market which has been installed throughout a wide environment from South America to Alaska in liners from 8” to 36” in diameter.”

ONEstep offers great benefits such as; easier introduction of initiator to resin, minimizing mixing problems and reduced initiator use, energy cost savings, labor savings, and safety.

PRESS RELEASE

FOR IMMEDIATE RELEASE

Advanced Marine Coatings with CoCure Technology Wins the 2018 IBEX Innovation Award

Structural Composites Inc is pleased to announce that Advanced Marine Coatings (AMC) with CoCure Technology has won the 2018 IBEX Innovation Award for Boat Building Materials. The entry featured a new US Navy SBIR Phase III – 9M EOD Advanced Combatant Craft that uses the new advanced coating as a commercial formulation.

In partnership with Interplastic Corporation CoCure AMC is now moving from the commercial transportation market and DOD market into the marine and RV markets. By combining polyurethane technology with polyester technology these new coatings provide user defined crack resistance and greatly enhanced weathering that is not possible with today’s conventional gel coats.

Scott Lewit President of Structural Composites says “Interplastic was able to advance our CoCure invention beyond our expectations. We loved the ability to ‘strain tune’ and adjust the elongation of the material as needed on a part, but we had no expectation that it would have a doubling in gloss and color retention and a huge improvement in abrasion resistance. Even better in our technical session at IBEX, Interplastic revealed new formulations in testing for the RV market that offer up to three times the weathering performance of todays’ polyester gel coats. This is very exciting as with these advanced coatings we can improve durability and lightweight existing products while simultaneously opening opportunities for composites in new markets all with a low HAP material!”.

Harry Certain Interplastic Product Manager says “The technology is changing the landscape of the composite market, providing better performing products for conventional markets, and opening doors to new ones. The innovative vision Scott and his team at Structural Composites have will impact resin chemistry for years to come. We are proud to be a part of it.”

Both companies will be displaying the technology at CAMX in Dallas, TX October 16-18, 2018. A technical educational session will be held at CAMX. CoCure is featured on the CAMX Award Finalist: The Future of Transportation- US Navy 7M advanced Combatant Craft. This is the team result of DOD and industry innovators collaborating in design, materials, electronics and marine propulsion into an advanced highly capable platform for our warfighters.

PRESS RELEASE

FOR IMMEDIATE RELEASE

Interplastic Corporation & Structural Composites Incorporated Partner to Promote Advanced Marine Coatings™ with CoCure™ Technology

Interplastic Corporation and Structural Composites Incorporated (SC) have formed a partnership to market Advanced Marine Coatings™. This product line uses Structural Composites Inc’s CoCure™ technology bringing the functionality of urethane chemistry to gel coats, allowing a higher performing product with regard to flexibility, weatherability and durability, all critical to the Marine industry.

“We are thrilled to be partnering with Structural Composites on this venture,” says Harry Certain, Business Manager for Interplastic Corporation. “SC is a leader in the development of composites for the marine industry. The discovery of the CoCure concept provides the marine market the tools to greatly improve boat design, improving performance and lowering overall cost.”

“Interplastic has taken our CoCure concept and made it a reality for gel coats in the marine market.” Says Scott Lewit, President of SCI. “Their expertise in gel coat technology and fundamental understanding of urethane chemistry has allowed a refinement of the product optimizing performance allowing the maximum benefits from the blend. Gel Coat is no longer a constraint to superior boat design.”

Both Companies will be displaying the technology at IBEX in Tampa, FL October 1-4, 2018. Interplastic Booth #753 and Structural Composites Booth #1242 & R14. Interplastic will also be at booth #N65 and Structural Composites at Booth #G62 during CAMX in Dallas, TX October 16-18, 2018. Technical educational sessions will be held at both events. The technology is also an entry for the 2018 IBEX Innovation Award and will feature a completed boat using the new coatings.

About Structural Composites

Structural Composites, Inc. (SC) is a division of The Composites Company (TCC), one of the nation’s leading composites technology development firms. TCC has three divisions: Structural Composites Inc., Compsys Inc. and Composites Intellectual Holdings Inc. Structural Composites. was founded in 1987 and has developed a proven track record of innovation and service in the composites industry. Over the years we have expanded our industry and technology base to include customers in the marine, aerospace, theme park, defense, and both road and rail transportation industries.

PRESS RELEASE

FOR IMMEDIATE RELEASE

CIPP Resins Designed to Renovate Pressure Pipes

(St. Paul, MN – June 16, 2016) Interplastic Corporation announced the release of a full line of cured-in-place pipe (CIPP) resins designed to renovate pressure pipes. These resins are designed to be used with liners containing a reinforcement component. Flexural creep retention factors tend to be higher than normal with these resins and short term burst test results have been impressive. These resins are designed to wet out the liner in an efficient manner and to gel and cure comparable to standard CIPP resins.